Getting fresh expectations is what every new year brings among individuals, brands, and industries. Talking about healthcare, oncology has seen a rapid development and demand—this shift is of maintaining higher standards, which is getting more serious than ever.

In recent years, cancer cases have risen globally, and pharma companies are living under pressure to deliver safer, faster, and effective treatments. This is where the need for Oncology CDMO trends is getting hype to get more cancer medications on time.

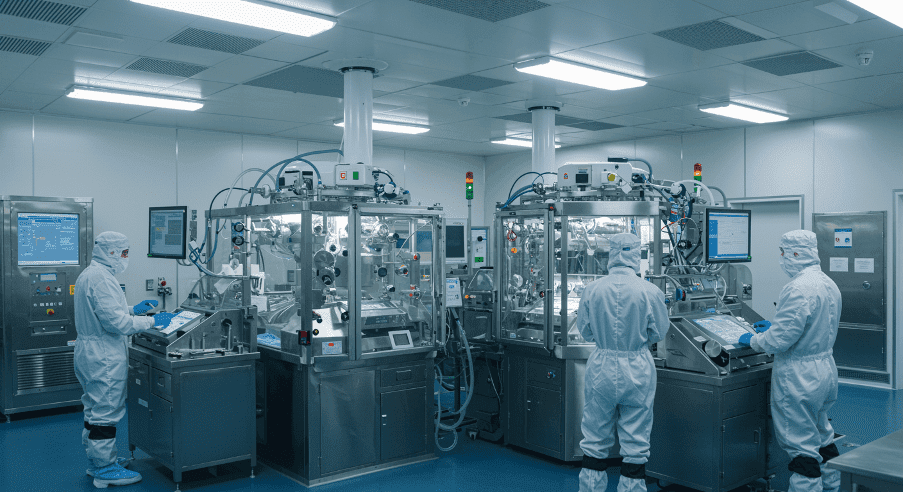

The idea of a new year, a new standard in oncology CDMO, gives better processes with stronger safety systems, with quality manufacturing. To manage the pressure of more cancer medications and precise treatments, pharma companies now expect partners dedicated to meeting international regulations, operating USFDA-Approved facilities, and supporting advanced cancer therapies. Today, Oncology CDMOs aren’t just medication manufacturing partners but real-time contributors to patient care.

Let’s get a more detailed perspective on the coming future of oncology CDMOs.

What Is an Oncology CDMO and Why Does It Matter Today?

Typically, an oncology CDMO ensures pharma brands or companies for the precise manufacturing of cancer drugs. The complexities in oncology medications aren’t manageable by all pharmaceutical companies because they need special facilities, trained staff, and strict safety control measures.

However, modern CDMOs are flexible and adapting to the new oncology CDMO trends like outsourcing complex drug production, managing high potency compounds, and supporting innovative drug formats. This makes pharma companies manage and reduce risk, save time, and keep focused on advanced research for drugs.

The “New Year, New Standard” Mindset in Oncology Manufacturing

Earlier cancer drug development was focused on the core goal of manufacturing medications at a precise scale. Yet today, the expectations have changed. Now, defining success is within quality, safety, compliance, and patient comfort as a priority. That shift has made USFDA-Approved within oncology CDMOs a preferable choice for global pharma companies.

The “New Year, New Standard” approach means:

- Global regulatory compliance

- Advanced manufacturing technology

- Safer handling of oncology drugs

- Faster time to market

Evolving oncology CDMO trends Shaping the Industry

Now there is a clear shift within modern oncology CDMO trends, keeping specialization and innovation. Today, oncology CDMO companies are heavily investing in advanced developments, modern infrastructure, and talent to meet the growing demand for industry trends.

Key trends include:

- Increased outsourcing of oncology drug manufacturing

- Expansion of biologics and targeted cancer therapies

- Stronger focus on regulatory readiness

- Development of patient-friendly dosage forms

Why USFDA-Approved Facilities Are the New Benchmark?

Well, the regulatory approvals are important in oncology manufacturing, and USFDA-Approved facilities ensure the following of strict rules over quality control, document approvals, and safety. When it’s about cancer drugs—oncology needs such approvals to build trust with regulators, doctors, and patients.

USFDA approval ensures:

- High manufacturing standards

- Accurate documentation

- Strong data integrity

- Reduced risk of product recalls

Growing Importance of antibody-drug conjugates

The biggest development in cancer treatment is antibody-drug conjugates. Such therapies do combine with targeted antibodies as a powerful cancer-killing medication. Therefore, it allows treatment for attacking cancer cells directly, yet doesn’t harm other healthy cells or tissues in the body.

Developing antibody-drug conjugates is complex and yet requires

- High-containment facilities

- Specialized equipment

- Skilled technical teams

Compliance and Security with BIOSECURE Act Compliant Facilities

Unlike development in pharmaceutical manufacturing, regulatory and national security concerns are an important part. Therefore, being BIOSECURE Act Compliant ensures following strict guidelines within data security, supply chain transparency, and manufacturing integrity. It helps for Oncology CDMOs as;

- Protect sensitive research data

- Ensure uninterrupted drug supply

- Build trust with global clients

Patient Comfort and the Rise of Modified-Release Oncology Tablets

Cancer treatments are harsh on the patient’s body, both physically and emotionally. It makes them exhausted, so modified-release oncology tablets are a little help, and of course, they are gaining popularity. These medications, over time, lower the need for frequent dosing—yet this happens at a slower rate.

Benefits of Modified Release Oncology Tablets include:

- Improved patient comfort

- Better drug absorption

- Fewer side effects

- Higher treatment adherence

Technology Is Redefining Oncology CDMO Operations

With advanced technological developments, the healthcare sector has been transformed, including the shift to oncology CDMO facilities. To improve accuracy and safety in cancer drug manufacturing, the implementation of automation, digital quality control systems, and real-time monitoring is important.

Modern oncology CDMOs use technology to:

- Reduce human error

- Improve batch consistency

- Enhance data tracking

- Speed up production timelines

Why Pharma Companies Prefer Specialized Oncology CDMOs?

That high risk and more investment are inseparable for cancer drug development. Collaborating with the best CDMOs helps in reducing the operational and regulatory challenges. Today, pharmaceutical brands look for CDMOs offering;

- USFDA-Approved manufacturing

- Expertise in antibody-drug conjugates

- BIOSECURE Act Compliant systems

- Capability to produce Modified Release Oncology Tablet

The Future of Oncology CDMO: What Lies Ahead

CDMO in oncology has a brighter future and is driven by innovation and responsibility. Today, cancer therapies have become more patient-centric and personalized, which requires more precise attention to manage the increasingly complex drug formats. The future of oncology CDMO development is likely to be with;

- Expansion of targeted therapies

- More focus on patient-centric drug design

- Stronger regulatory oversight

- Wider adoption of digital manufacturing

The Final Verdict:

The years have passed, and the healthcare sector has always been transforming, including cancer drug manufacturing. Rising expectations on quality, safety, compliance, and innovation are getting a more precise shape. The growing oncology CDMO trends and increased reliance on USFDA-Approved facilities, with increased demand, have emphasized cancer drugs and therapies. This new standard ultimately benefits patients by ensuring safer, more effective, and more accessible cancer treatments worldwide.

FAQs

Why are oncology CDMOs important for cancer drug development?

Oncology CDMOs provide specialized facilities and expertise needed to safely manufacture complex cancer medicines while meeting global regulatory standards.

What makes USFDA-approved oncology CDMOs more reliable?

USFDA-Approved oncology CDMOs follow strict quality and safety rules, reducing regulatory risks and ensuring high-quality cancer drug production.

How do modified-release oncology tablets help cancer patients?

Modified Release Oncology Tablets release medicine slowly, reducing side effects and improving comfort during long-term cancer treatment.